Multi-functional Plastic Vacuum Forming Machine – Precision Manufacturing of Egg Trays, Lids, and Incubators

Application Scope

1. Plastic packaging industry: Blister machines are widely used to produce various plastic packaging boxes, decorative boxes, frames and other products, suitable for batteries, toys, gifts, hardware, home appliances, electronics, stationery, decoration and other fields.

2. Food packaging industry: In the food packaging field, blister machines can produce fast food boxes, fruit trays, biscuit boxes, etc. to maintain the freshness and hygiene of food.

3. Pharmaceutical industry: In the pharmaceutical field, blister machines are used to produce pill packaging, tablet packaging, etc. to ensure the safety and hygiene of medicines.

4. Industrial applications: Blister machines are also used to produce industrial accessories such as cooling water guide plates for industrial cooling towers.

5. Daily necessities and electronic product packaging: Blister machines are suitable for the production of blister packaging for daily necessities, electronic products, computer peripherals, toys, sporting goods, and stationery.

Description

WX-1220 Vacuum Forming Machine

This image shows a CE-certified plastic vacuum forming machine, ideal for manufacturing food containers and trays. It features advanced forming technology for efficient plastic product production.

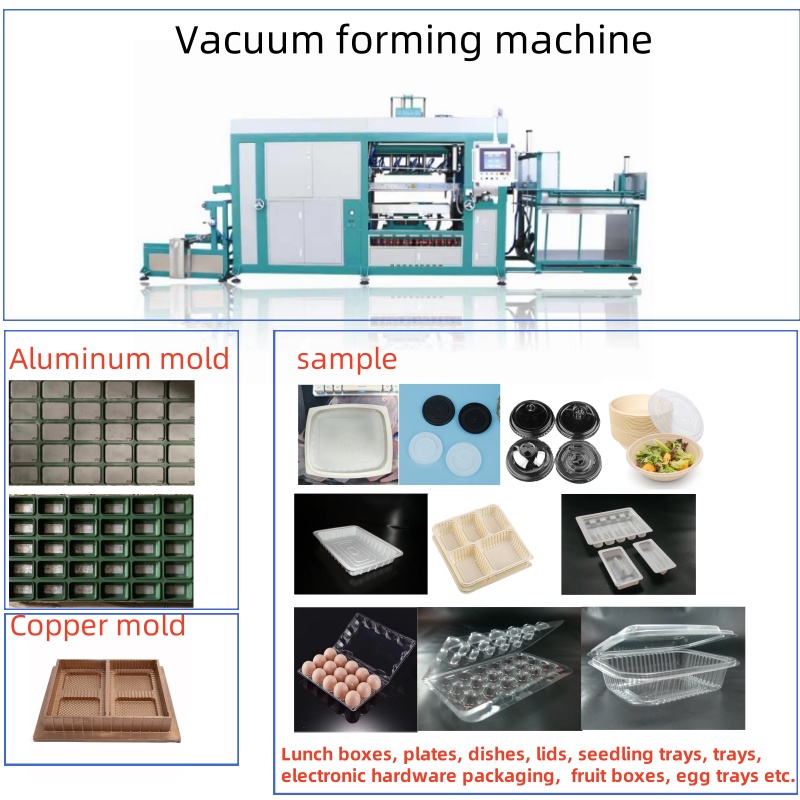

Vacuum forming machine mold

This image shows various molds and corresponding products made by our vacuum forming machine, including food containers and trays. It illustrates the machine’s mold customization capability for different plastic packaging needs.

Main technical parameters

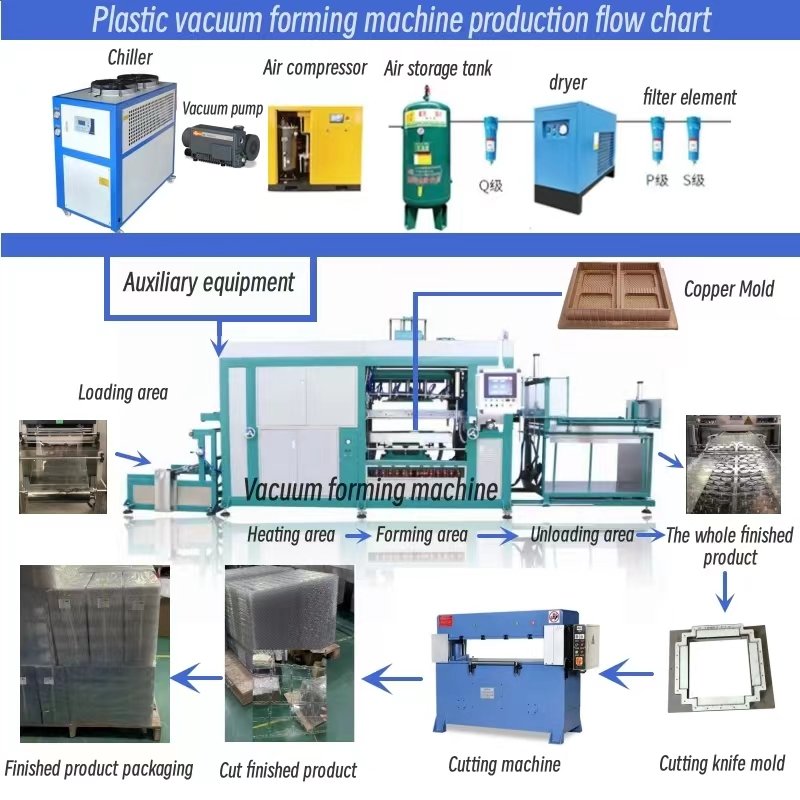

This image shows the complete production flowchart of a plastic vacuum forming machine, detailing steps for food container and tray manufacturing. It visualizes the efficient production process.

Our Advantages

This image highlights our factory’s advantages in producing plastic machinery, including advanced manufacturing capabilities and strict quality control for vacuum forming equipment.

1、with CE certification

2、Free replacement of parts

3、Lifetime technical support

4、Localized services in Southeast Asia

5、Free lifetime after-sales service

6、0n-site installation and debugging

7、online teaching videos

CE Certificate

This image displays the CE certificates of our plastic cup making machine, confirming it meets EU safety, health, and environmental protection standards. It ensures the machine’s compliance for international trade and use in the food packaging industry.

Visit customer factory

This image shows our technical team providing on-site after-sales repair service for plastic machinery at an overseas customer factory. It reflects our commitment to global customer support.

Our Exhibitions

This image shows our trade show booth at an exhibition, showcasing plastic cup making machines and other plastic machinery products. It highlights our presence in the industry and the opportunity to explore our equipment in person.

FAQ

1、What products can the vacuum forming machine make?

Egg trays, fruit boxes, seedling trays, fast food boxes, sushi boxes, electronic trays, cake boxes, plastic trays, etc.

2、What does the full set include?

Vacuum forming machine, air compressor, chiller, vacuum pump, gas tank, cutting machine

3、Area occupied?

Full equipment workshop area: 200-400 square meters.

4、How many workers are needed?

Only 1-3 people are needed (responsible for equipment monitoring, packaging and maintenance).

5. What is the hourly output of the vacuum forming machine?

Different products have different outputs (depending on the product)

6、Payback period?

The payback period is about 4 months (depending on the order quantity and unit price).

7、What after-sales maintenance is there?

24-hour Arabic/English technical support, on-site installation training team, equipment lifetime upgrade service.

8、What are the special advantages of the machine?

Install cooling fan, moisture-proof circuit;Filtered dust-proof air intake, high temperature resistance; Customizable voltage, rat-proof cable.Easy to operate, can be on duty in a few hours