High-Speed Plastic Extruder Machine – PP Sheet Extrusion Line for Recycling Production

Application Scope

PP(polypropylene) extruder products:Sheet: Suitable for the production of polypropylene (Pp) and other plastic sheetswhich can be used to make beverage cups, ice cream cups, jelly cups, packagingboxes and other packaging containers

PS (polystyrene) extruder products:

Sheet material: Suitable for the production of PC/PS/PMMA products, mainly used inthe automotive industry, electronics, electrical industry membrane switches,computers, mobile phones, business communication LCD screens, etc.

Description

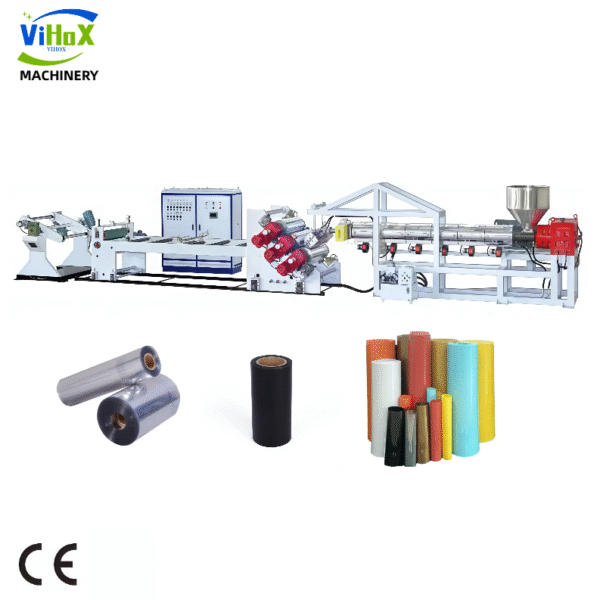

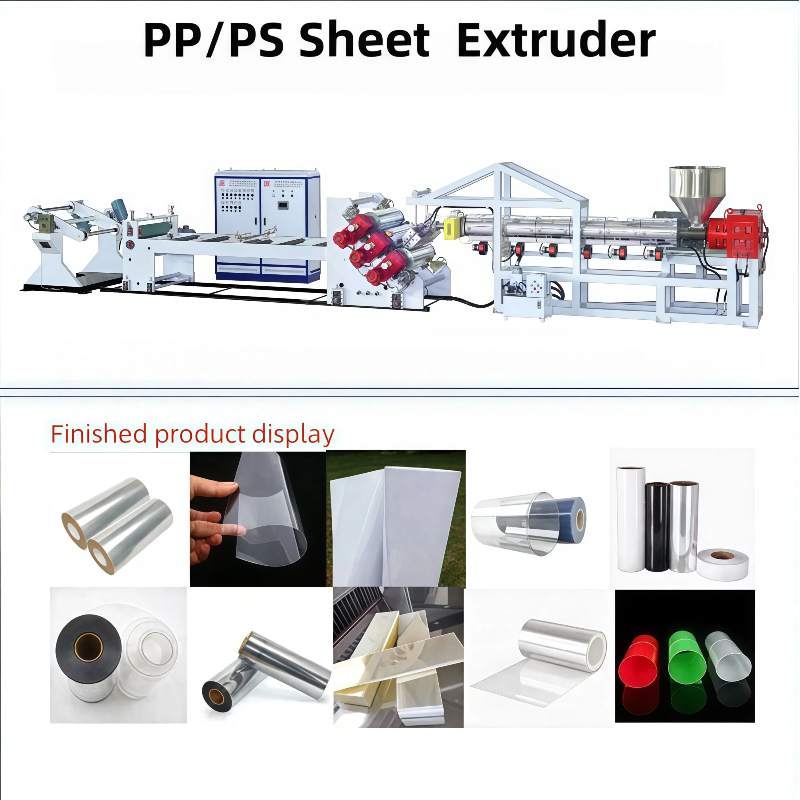

PP/PS Sheet Machine

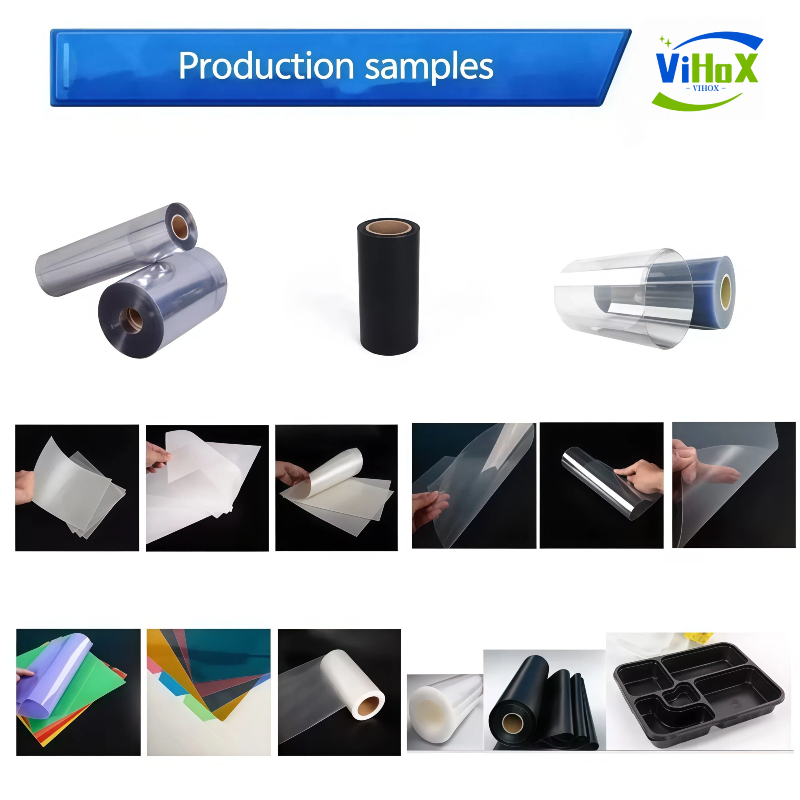

This image shows a PP/PS sheet extrusion machine and its produced plastic sheets, suitable for packaging, blister products, and industrial applications. It demonstrates the machine’s capability to create diverse sheet materials.

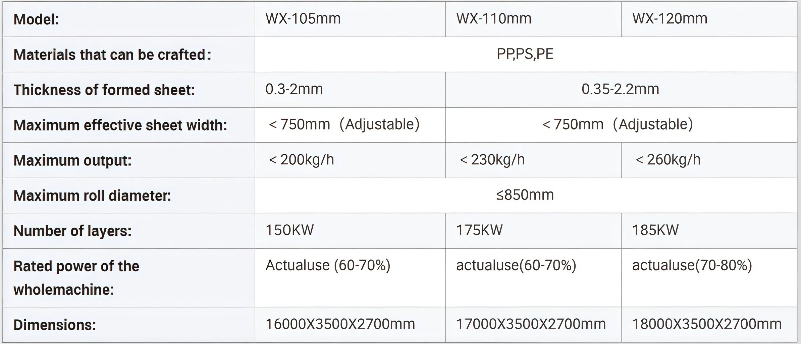

parameter

This image displays the main technical parameters of a PP/PS sheet extrusion machine, including capacity, speed, and dimensions for plastic sheet production. It aids in assessing machine suitability.

Complete production process

This image shows the complete production flowchart of a PP/PS sheet extrusion machine, detailing steps from raw material feeding to finished sheet output. It visualizes the efficient manufacturing process.

Our Services

1、with CE Certification

2、Free replacement of parts

3、Lifetime technical support

4、Free lifetime after-sales service

5、Localized services in SoutheastAsia

6、0n-site installation and deblgging

7、Production formula guidance

CE certificate

This image displays the CE certificates of our plastic cup making machine, confirming it meets EU safety, health, and environmental protection standards. It ensures the machine’s compliance for international trade and use in the food packaging industry.

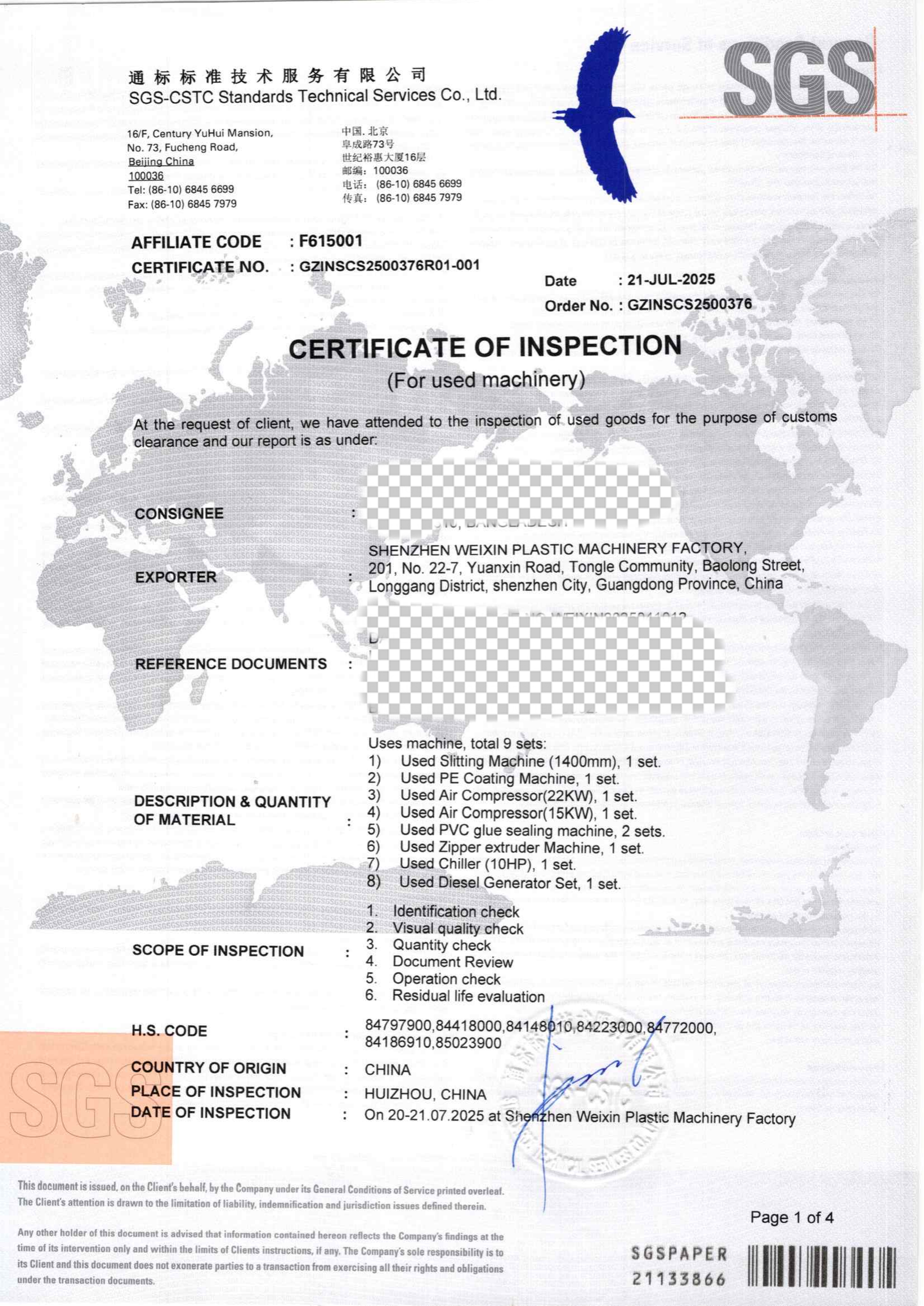

Testing agency certificate

This image shows our SGS certification for plastic machinery, including vacuum forming and cup making equipment. It proves compliance with international quality and safety standards.

Our Exhibitions

This image shows our trade show booth at an exhibition, showcasing plastic cup making machines and other plastic machinery products. It highlights our presence in the industry and the opportunity to explore our equipment in person.

FAQ

1、What materials can the sheet machine produce?

Sheet extruder can produce PP、PS、PET

2、What does the full set include?

Sheet extruder, cooling tower, feeder, mixer, crusher, air compressor

3、Area occupied?

Full equipment workshop area: 400-600 square meters.

4、How many workers are needed?

Only 4 people are needed (responsible for equipment monitoring, packaging and maintenance).

5. What is the hourly output of the vacuum forming machine?

Different materials have different outputs (150-600kg/h)

6、Payback period?

The payback period is about 4 months (depending on the order quantity and unit price).

7、What after-sales maintenance is there?

24-hour Arabic/English technical support, on-site installation training team, equipment lifetime upgrade service.

8、What are the special advantages of the machine?

Install cooling fan, moisture-proof circuit;Filtered dust-proof air intake, high temperature resistance; Customizable voltage, rat-proof cable.Easy to operate, can be on duty in a few hours