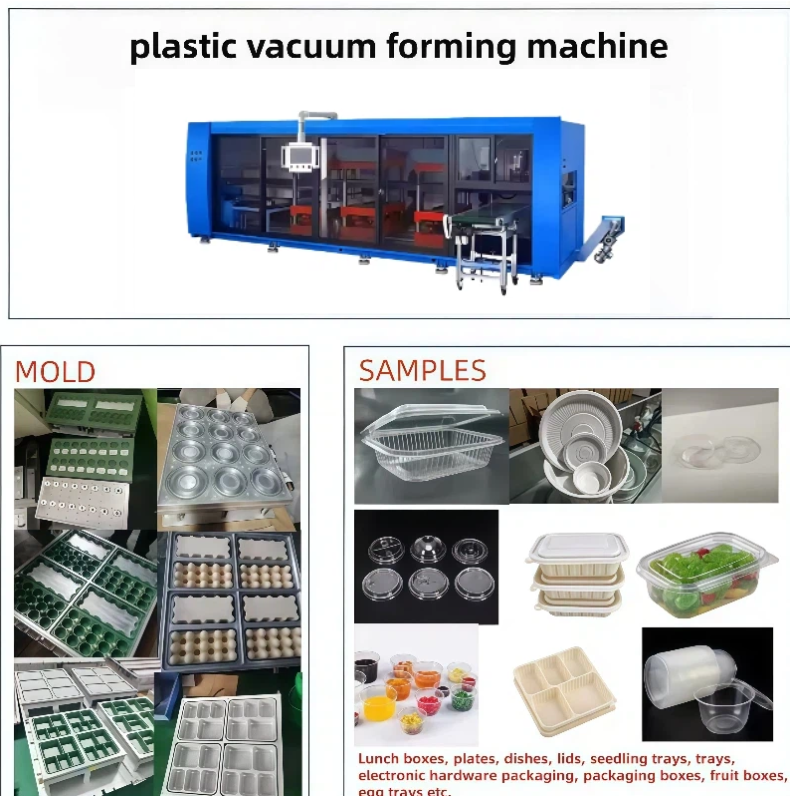

Fully Automatic Three-Station Plastic Sauce Box Vacuum Forming Machine

A three-station vacuum forming machine is an industrial, fully automatic system that integrates the separate stages of plastic forming into three distinct operational areas (stations) to enable high-speed, continuous production. These machines are primarily used for efficient mass production of disposable or high-volume plastic packaging and products.

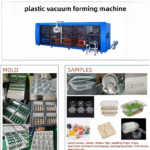

- Forming Station: A sheet of plastic material (fed continuously from a roll) is heated and then formed into the desired shape using vacuum pressure and a mold tool. This station may use positive and negative pressure to achieve detailed shapes.

- Cutting/Punching Station: Once formed and slightly cooled, the individual products are cut or punched out from the larger plastic sheet by a specialized cutting mechanism.

- Stacking/Collecting Station: The finished, cut products are automatically stacked and prepared for packaging, while the skeletal waste material from the sheet is often collected separately for recycling.

Description

Fully automatic three-station plastic vacuum forming machine

Detailed structural diagram of plastic vacuum forming machine, showing components for egg tray and lunch box production.

Molding mold

Different molds of plastic vacuum forming machine producing egg trays, dishes, lunch boxes and more.

Main technical parameters

This image displays the main technical parameters of a plastic vacuum forming machine, including capacity, dimensions, and power for food container production. It helps customers assess machine suitability.

Products that machines can make

Products made by plastic vacuum forming machine, including trays, dishes, food containers, demonstrating multi-product manufacturing ability.

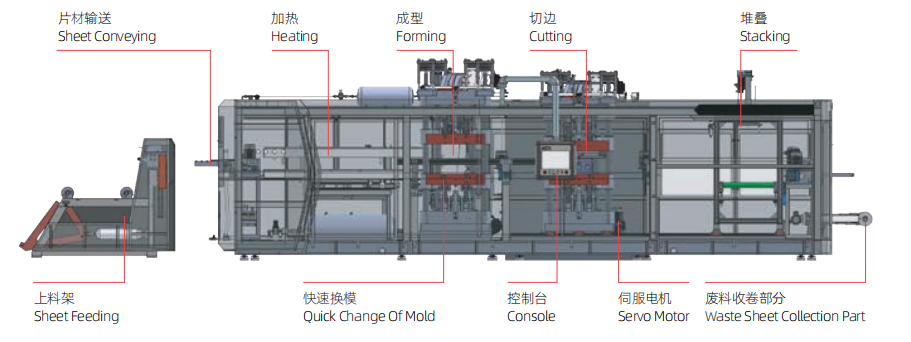

The whole process of the cup making machine

Products made by plastic vacuum forming machine, including trays, dishes, food containers, demonstrating multi-product manufacturing ability.

CE certification

This image displays the CE certificates of our plastic cup making machine, confirming it meets EU safety, health, and environmental protection standards. It ensures the machine’s compliance for international trade and use in the food packaging industry.

Our Exhibitions

This image shows our trade show booth at an exhibition, showcasing plastic cup making machines and other plastic machinery products. It highlights our presence in the industry and the opportunity to explore our equipment in person.

Visit customer factory

This image shows our technical team providing on-site after-sales repair service for plastic machinery at an overseas customer factory. It reflects our commitment to global customer support.

Our Services

1、with CE Certification

2、Free replacement of parts

3、Lifetime technical support

4、Free lifetime after-sales service

5、Localized services in SoutheastAsia

6、0n-site installation and deblgging

7、Production formula guidance

Machine advantages

This machine features fully automatic functions for heating, forming, cutting, stacking, and counting. It utilizes a servo control system and incorporates advanced automation systems, ensuring consistently high-quality production, whether processing PP, PET, PS, PVC, PE, or PLA. Applications:

1. Food packaging: including fresh fruit and vegetable boxes, egg trays, and mooncake trays, for food protection and display.

2. Electronic trays: used for packaging and transporting electronic products, providing shockproof protection.

3. Seedling trays and flower pots: used in agriculture and horticulture as containers for plant growth.

4. Pharmaceutical packaging: such as injection trays, solid medication trays, and bottle trays, ensuring the safety and hygiene of pharmaceuticals.

5. Tool packaging: used for outer packaging of finished tools, providing protection and easy portability.

6. Wine packaging: such as wine bottle packaging and fixed trays.

7. Toy packaging: used for packaging and protecting children’s toys.

8. Cosmetic packaging: used for cosmetic packaging, providing aesthetics and protection.

FAQ

1、What products can the fully automatic three-station positive and negative pressure integrated machine make?

Egg trays, fruit trays, seedling trays, fast food trays, sushi trays, electronic trays, cake boxes, plastic trays, fresh fruit and vegetable boxes, moon cake trays, etc.

2、What does the full set include?

Vacuum forming machine, air compressor, chiller, vacuum pump, gas tank, cutting machine

3、Area occupied?

Full equipment workshop area: 300-500 square meters.

4、How many workers are needed?

Only 1-3 people are needed (responsible for equipment monitoring, packaging and maintenance).

5. What is the hourly output of the vacuum forming machine?

Different products have different outputs (depending on the product)

6、Payback period?

The payback period is about 4 months (depending on the order quantity and unit price).

7、What after-sales maintenance is there?

24-hour Arabic/English technical support, on-site installation training team, equipment lifetime upgrade service.

8、What are the special advantages of the machine?

Install cooling fan, moisture-proof circuit;Filtered dust-proof air intake, high temperature resistance; Customizable voltage, rat-proof cable.Easy to operate, can be on duty in a few hours